Product Details

2-spindle Vertical Grinder

HVG-300DSO

The 2-spindle vertical grinder HVG-300DSO equip a sliding work spindle that pursues high-quality precision grinding.

Grinding can be performed on the same platform without removing the workpiece from the work chuck during the process of changing the wheel for rough grinding and fine grinding by one grinding machine, enabling high-precision dimensional control and reduction of machining error.

Machine Specification

MODEL : HVG-300DSO

| Machine Model | HVG-300DSO |

|---|---|

| Work Transfer Method | Slide Way |

| Wheel Diameter (mm) x No of Spindles |

⌀305 x 2 |

| Wheel Speed (rpm) | 2,000 |

| Wheel Spindle Motor (kW) | 7.0 |

| Work Table Diameter (mm) | 350 |

| Work Table Speed (rpm) | 400 |

| Dimension (W x D x H mm) | 1,400 x 1,870 x 2,400 |

| Weight (Kg NET) | 4,300 |

2-spindle Vertical Grinder

HVG-300DSR

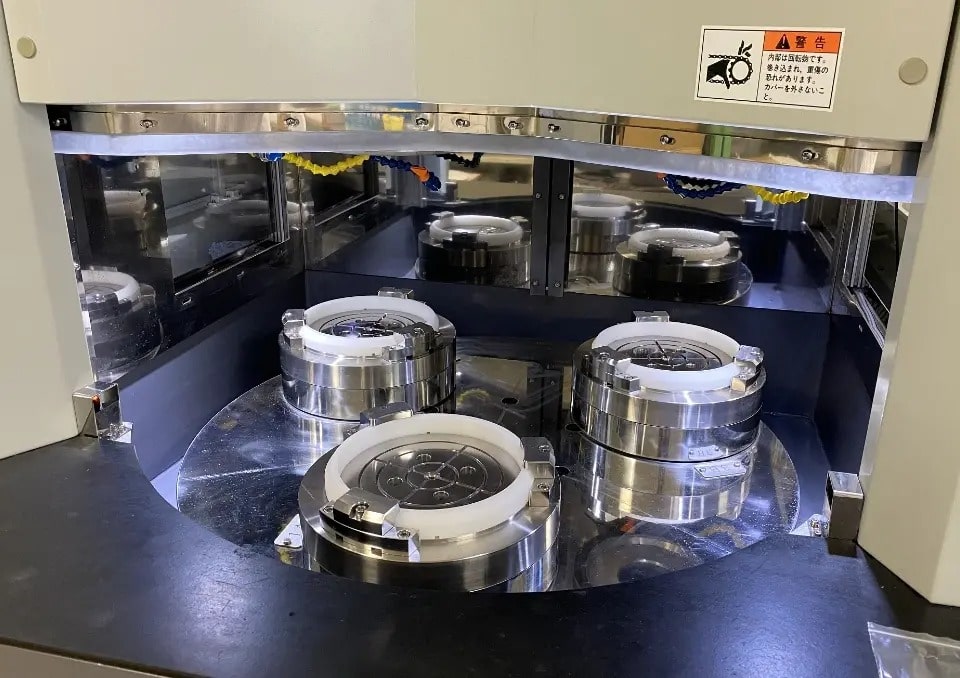

The 2-spindle vertical grinder HVG-300DSR uses a rotary work spindle that pursues high efficiency grinding.

A single grinding machine can grind the workpiece on the rotary table in the process of rough grinding and fine grinding in same time enabling highly efficient grinding.

Machine Specification

MODEL : HVG-300DSR

| Machine Model | HVG-300DSR |

|---|---|

| Work Transfer Method | Rotation |

| Wheel Diameter (mm) x No of Spindles |

⌀255 x 2 |

| Wheel Speed (rpm) | 3,000 |

| Wheel Spindle Motor (kW) | 5.0 |

| Work Table Diameter (mm) | ⌀250 x 3 |

| Work Table Speed (rpm) | 400 |

| Dimension (W x D x H mm) | 1,450 x 2,100 x 2,100 |

| Weight (Kg NET) | 5,000 |

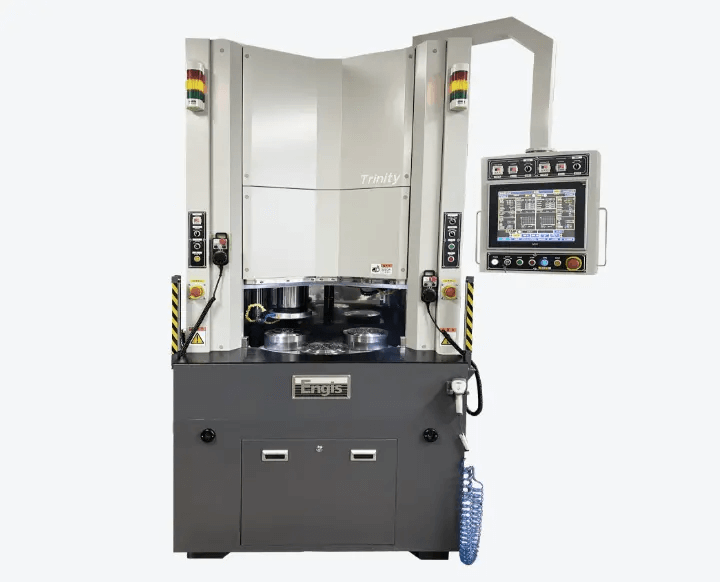

Advanced Options

HVG-AD and HVG-ADM models are available with optional controls for automatic wheel dressing, automatic positioning of the wheel relative to the workpiece, and workpiece thickness measurement. For maximum control, upgrade to in-process thickness measurement with real-time feedback to the grinding cycle. ADM models offer options for automated thickness measurements, including multi-point contact probing for grinding multiple wafers, or a choice of contact or non-contact continuous in-process measurement of single wafers.

Related Products