Product Details

Lapping Plates

An efficient lapping process requires proper lapping plate selection. Select a plate according to the purpose of processing (stock removal, surface roughness), processing material, and size/type of diamond slurry used for lapping.

Each material of HYPREZ plate is a composite of high-molecular-weight polymer and metal powder, which has a certain degree of flexibility and elasticity, holds diamonds uniformly, and converts them into fixed abrasive grains. It can significantly reduce process time and achieve a fine surface finish.

ALMET plate is a surface plate made by mixing special metals with tin as a base and performing crystal grain refining treatment. Stable surface roughness, polishing rate, and plate life can be obtained compared to pure tin.

Specification

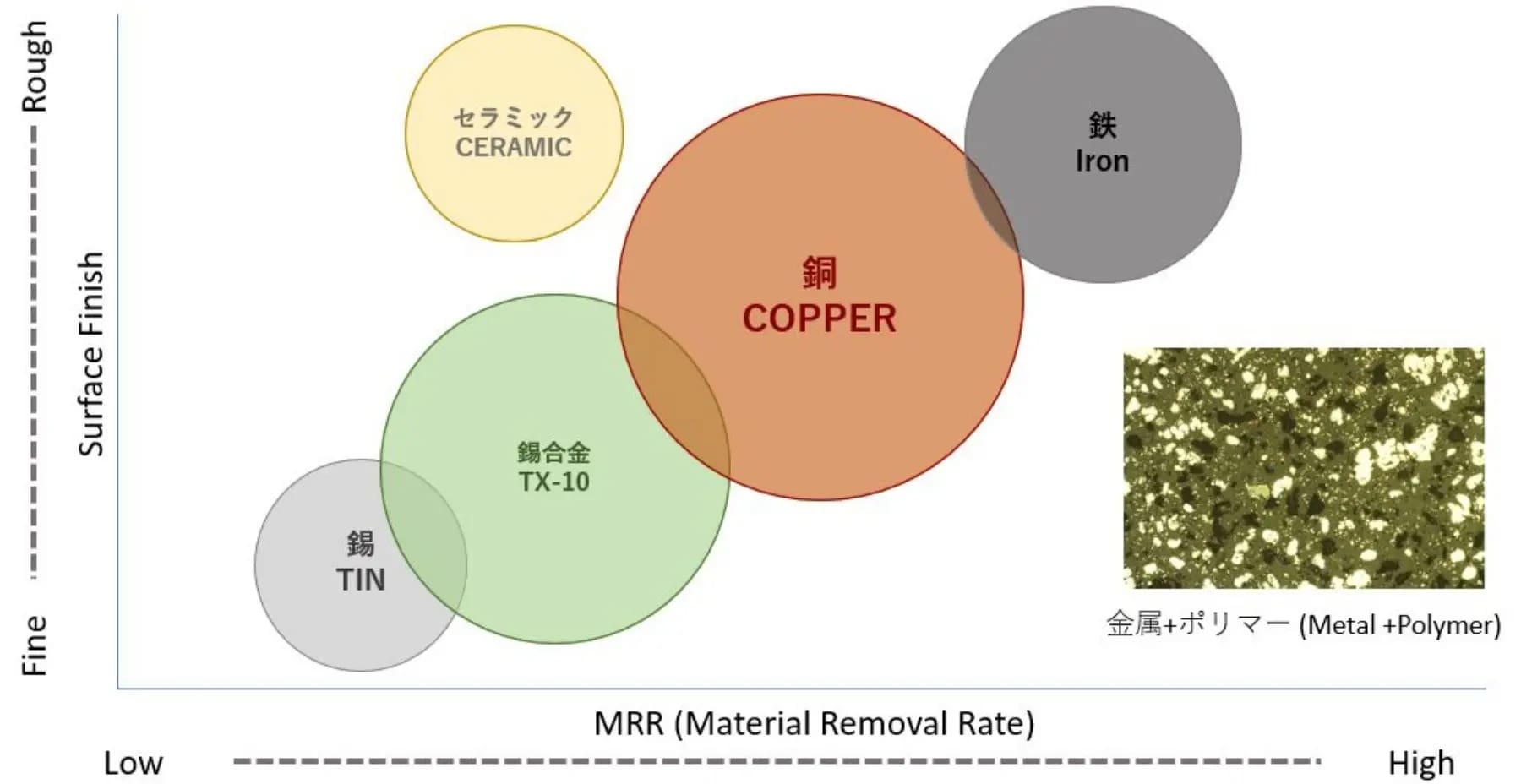

Hyprez IRONSuitable for processing requires a large amount of lapping.

Hyprez CopperSuitable for semi-finishing. The most universal plate.

Hyprez Tin (TX-10) Used for final finishing and suitable for processing before polishing.

Hyprez TinUsed for final finishing and suitable for processing before polishing.

Hyprez CeramicComposite ceramic plate; used when metal free processing is required.

ALMET PlateTin alloy lapping plate made by mixing special metals with performing crystal grain refining. Stable surface roughness, lapping rate, and plate life can be obtained compared to pure tin.

| Diamond Grain Size | Lap Plate Selection | |||||||

|---|---|---|---|---|---|---|---|---|

| Micron Size | Micron Range | Mesh Size | ||||||

| 1/10 | 0-1/5 | 240,000 | ||||||

| 1/8 | 0-1/4 | 200,000 | ||||||

| 1/4 | 0-1/2 | 100,000 | ||||||

| 1/2 | 0-1 | 60,000 | ||||||

| 1 | 0-2 | 14,000 | ||||||

| 2 | 1-3 | 11,000 | ||||||

| 3 | 2-4 | 8,000 | ||||||

| 6 | 4-6 | 3,000 | ||||||

| 9 | 8-12 | 1,800 | ||||||

| 15 | 12-22 | 1,200 | ||||||

| 30 | 22-36 | 600 | ||||||

| 45 | 36-54 | 325 | ||||||

HYPREZ Iron

HYPREZ Copper

HYPREZ TX-10

HYPREZ Tin

HYPREZ Ceramic

Almet Series

Related Products