Product Details

Vertical Grinding Machine

HVG Series

The vertical grinding machine EVG series has a lineup that matches the wafer size. A compact and highly rigid body structure suitable for research and development institutes to mass production. By combining with other Trinity series, you can save space and build a high-performance machining system.

Machine Specification

MODEL : HVG-200

| Machine Model (HVG-xxx) | 200 | 250 | 300 |

|---|---|---|---|

| Work Size | ~4inch | ~6inch | ~8inch |

| Wheel Diameter (mm) | 200 | 250 | 300 |

| Wheel Speed (rpm) | 2,000 | ||

| Work Table Diameter (mm) | 200 | 250 | 300 |

| Work Table Speed (rpm) | 400 | ||

| Dimension (W x D x H mm) | 800 x 800 x 1,900 | 1,000 x 1,100 x 1,900 | 1,050 x 1,050 x 2,200 |

| Weight (Kg NET) | 1,100 | 2,000 | 2,500 |

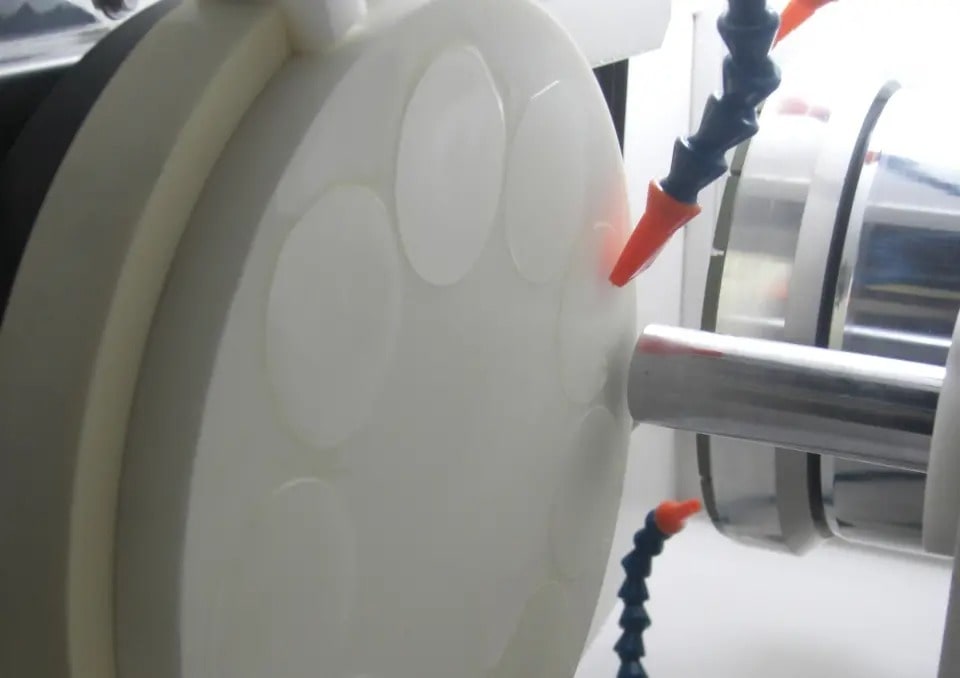

Horizontal Grinding Machine EHG Series

The horizontal grinding machine EHG series is equipped with a soft touch panel, enabling high-precision grinding with simple operation. Closed-loop control is performed by combining a grinding wheel axis equipped with a high-precision spindle, a work axis and an oscillating motion with an optical linear scale to achieve higher feed accuracy and sizing accuracy. Especially suitable for surface grinding of small parts and small diameter wafer grinding.

Machine Specification

MODEL : EHG-250

| Machine Model (EHG-xxx) | 170 | 180 | 250 |

|---|---|---|---|

| Work Size | ~4inch | ~6inch | ~8inch |

| Wheel Diameter (mm) | 170 | 180 | 250 |

| Wheel Speed (rpm) | 2,500 | 2,000 | |

| Work Table Diameter (mm) | 170 | 180 | 250 |

| Work Table Speed (rpm) | 560 | 400 | 300 |

| Dimension (W x D x H mm) | 1,300 x 620 x 1,300 | 1,250 x 700 x 1,300 | 1,200 x 780 x 1,450 |

| Weight (Kg NET) | 800 | 820 | 900 |

Advanced Options

EVG-AD and EVG-ADM models are available with optional controls for automatic wheel dressing, automatic positioning of the grinding wheel relative to the workpiece, and workpiece thickness measurement. For maximum control, upgrade to in-process thickness measurement with real-time feedback to the grinding cycle. ADM models offer options for automated thickness measurements, including multi-point contact probing for grinding multiple wafers, or a choice of contact or non-contact continuous in-process measurement of single wafers.

Related Products